After some troubles with my electric choke/enricher, I decided to install a Hoca, manual choke.

Throughout my research, I didn’t see many threads on this topic, nor any about installation. Here is my contribution.

This scooter is new and since day 1, the choke would cut out within a minute of starting and I’d have to use the throttle to keep it from stalling.

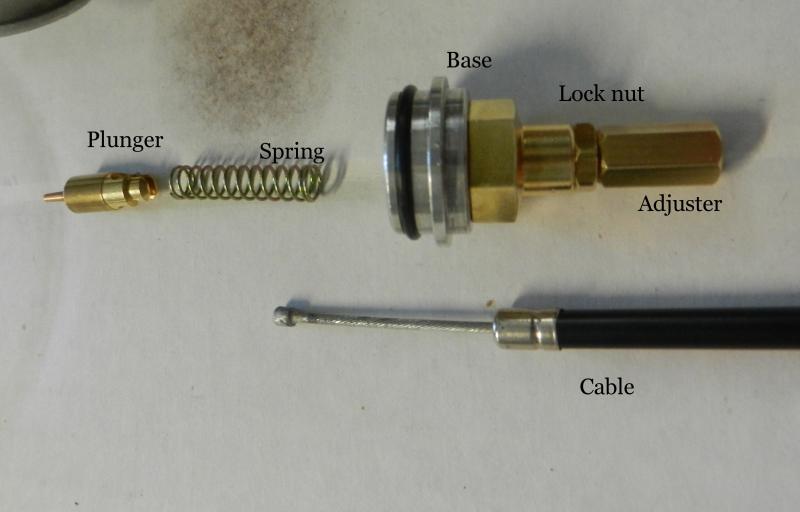

There are 2 parts needed for this … the manual choke kit and the cable; both parts I got from PFS for $31.

On my first attempt, I got the kit installed, but had some issues. The tension on the spring was so great, it would pull the plunger back in. You pull the choke out, let go and by the time you’d start the bike, it would be back in … that was no good.

For attempt #2, I checked at my local hardware store for springs. I bought 2, one that was about the same tension, but shorter and another that was longer, but much lighter in tension. I ended up using the longer one.

Installation:

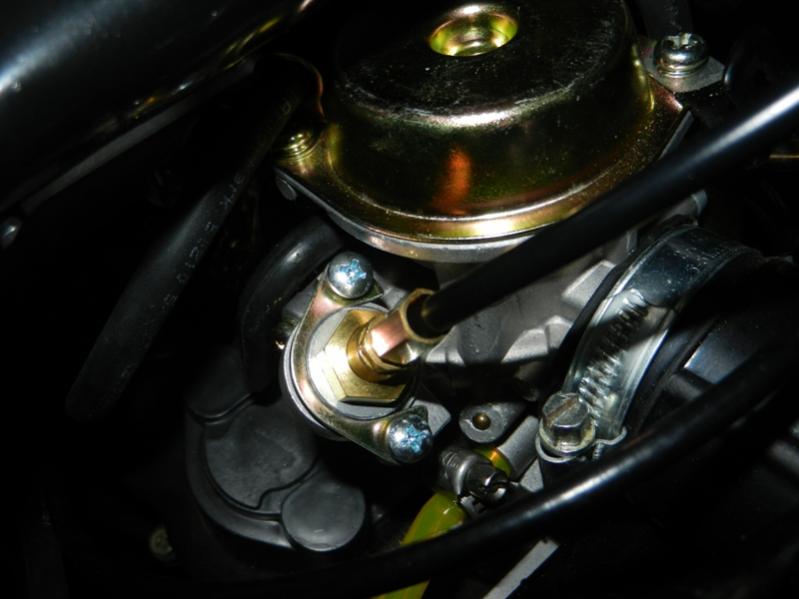

The cable is 2 feet long so it must be located close to the engine. I chose a spot under the front of the seat, centered on the engine cover. It’s a convenient location, not in the way, and easy to reach. Once a hole is drilled and the cable is inserted, the nut is slid up the cable and tightened down from the rear. There was some interference from the air cleaner snorkel, but it flexed enough to get around it. I followed the same side as the air intake so that the cable loops around the back of the carb to the choke housing.

There are 2 pieces that make up the base, they are screwed together. Assembly is done by threading the cable through the base, sliding the spring over the cable end, and attaching the plunger by sliding sideways onto the ferrule at the cable end.

I found it helpful to compress the spring/hold it in place with needle-nosed pliers. When the spring is released, it covers the slot, holding the plunger in place.

There is a thin rubber washer that fits in the choke housing; install the washer, then holding the cable, slide the plunger into the opening.

While pushing in the plunger, seat the base and secure it with the original retainer.

I found it easiest to start the bottom screw and swing the retainer out of the way, then rotate it up and in place once the base is seated (the kit comes with a retainer, but doesn’t hold the base in properly; the original retainer is reused, but had to be widened slightly to fit around the new base. A dremel with a sanding drum made quick work of that).

Adjustment:

I found that by pulling slightly on the cable you could feel the play in the cable, from the base, as well as feeling the plunger unseat. I simply backed out the adjuster until the cable play was gone, and then secured the lock nut (8mm).

Here are some video clips ...

Before:

After:

Thanks for reading,

Gene